SUSS Supports IMT Production Ramp Up For MEMS Devices

Munich, Germany -- SUSS MicroTec, a supplier of precision manufacturing equipment for the semiconductor and emerging markets, announced the installation of an additional wafer bonding system at Innovative Micro Technology in Santa Barbara, CA.

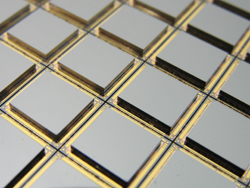

Munich, Germany -- SUSS MicroTec, a supplier of precision manufacturing equipment for the semiconductor and emerging markets, announced the installation of an additional wafer bonding system at Innovative Micro Technology in Santa Barbara, CA.Innovative Micro Technology (IMT) required additional wafer bonding capacity as part of its ramp up to volume production on several new MEMS products. These include novel patented IR emitters as well as MEMS switch products, both of which are now in production at IMT's wafer fab, now in 24x7 operation.

"We're shipping over one million working MEMS switches every week and wafer bonding is a critical step and a core competency. These and our other devices have stringent process requirements both in terms of hermeticity and wafer yield. SUSS wafer bonders have demonstrated their ability to meet our manufacturing needs," said John Foster, CEO of IMT.

"We are pleased that our wafer bonders have the flexibility and performance to meet the needs of a leading MEMS foundry such as IMT, as evidenced by the repeat order for production tools"; said Michael Kipp, General Manager Wafer Bonder Division, SUSS MicroTec.

SOURCE: SUSS MicroTec