New System Cuts Sealing Costs for Small Ceramic Packages

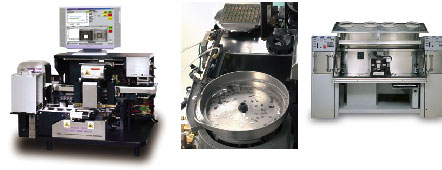

Parallel seam sealing technology provides the most effective, uniform sealing available. High yields are guaranteed by lid placement automation and digital sealing power. Full PC control, with convenient Windows® user interface, manages all operating parameters.

Systems are configured with lid tacking stations outside the drybox. Complete lid sealing occurs after the moisture removal process and inside the drybox in an inert environment. SSEC's automatic gas mixing with helium enables fine leak testing immediately following the sealing process.

Solid State Equipment Corporation manufactures a full line of single wafer cleaners/processors and hermetic package sealers at its headquarters in suburban Philadelphia. These systems are complemented with application-specific components and supporting systems, including chemistry management systems and environmental systems for sealers. SSEC maintains sales and service offices worldwide, and customer support and process development centers in Horsham, Pennsylvania, Fremont, California, Regensburg, Germany, and Tokyo, Japan. For further information, contact Terri Kolodziejski at SSEC, 215-328-0700, FAX 215-328-9410, tkolodziejski@ssecusa.com.

Solid State Equipment Corporation, 185 Gibraltar Road, Horsham, PA 19044. Tel: 215-328-0700; Fax: 215-328-9410.