Mallinckrodt Baker Delivers Residue Remover For 90-nm Silicon Wafer Processing

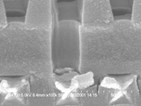

Phillipsburg, NJ - Following the introduction of cleaning products for the 65 nanometer (nm) and 45 nm wafer technology nodes, Mallinckrodt Baker, Inc., is making BAKER CLk-870 residue remover available as a cost-effective wet clean product designed to remove inorganic residue and post-etch/ash polymer from 90 nm single-wafer processes. According to Mallinckrodt Baker, BAKER CLk-870 residue remover provides fast cleaning action and low process temperatures, making it an ideal chemistry for silicon nitride, copper and delicate low-k substrates.

"As copper/low-k processes move into mature markets, it is essential to deliver cost-effective solutions," said Terry McGovern, global marketing director – microelectronics for Mallinckrodt Baker. "BAKER CLk-870 residue remover satisfies the market need to reduce operational costs, without sacrificing performance."

The global demand for chemistries that provide significant cost savings on mature technology platforms continues to increase as wafer fabrication facilities look to incorporate methods to reduce operational costs. Following the successful launch of BAKER CLk-888 residue remover, a wet cleaning product for the 65 nm node, and its successor, BAKER CLk-222 residue remover for the 45 nm node, the company recognized an opportunity to address the cost reduction initiative for fabs that have incorporated a dry photoresist removal step in their process scheme. Fully compatible with copper and low-k dielectrics, BAKER CLk-870 residue remover is a solution that addresses this market need.

With an etch rate of <1 Å per minute at 75°C for copper and deposited low-k , the residue remover is designed for use in single-wafer processors, spray tools or bath systems, and boasts a bath life that is typically greater than 24 hours. Designed to provide broad latitude in terms of processing time and temperature, the residue remover achieves normal process times of 30 seconds for single-wafer tools and 10 minutes for spray and bath treatment at typical process temperatures of 45°C-75°C.

BAKER CLk-870 residue remover is a 100 percent water-soluble formulation, so it does not require an intermediate solvent rinse. The elimination of the intermediate solvent rinse decreases total process time, thereby reducing operation costs. BAKER CLk-870 residue remover is available now along with the company's BAKER CLk-888 product for 65 nm and BAKER CLk-222 for 45 nm processing.

For more information, you can visit http://www.mallbaker.com/micro.

SOURCE: Mallinckrodt Baker, Inc.