Heraeus Optical Plate – New Approach to Plano Optics Manufacture

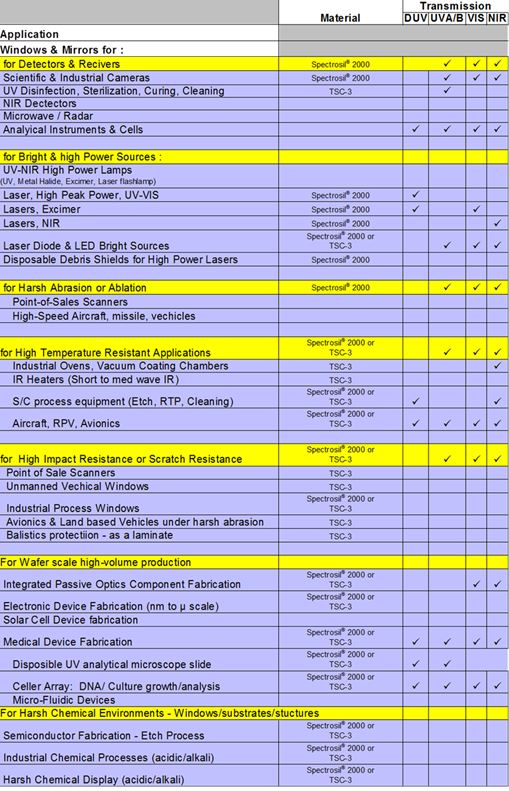

Optical Plates made from Heraeus Spectrosil 2000 and Heraeus TSC-3 Fused Silica benefit from the unique optical, thermal, mechanical, electrical, and chemical properties that fused quartz and fused silica provides.

Cost Effective plate forming - Heraeus combines a near-net-shape material manufacturing process and efficient large area wire saw and double sided polishing with these materials to produce optical plates with unique performance benefits and other differential advantages over other bulk fused silica & fused quartz products and in some cases other materials.

Unique Optical Properties - Fused silica and fused quartz offer a wide transmission range (DUV to NIR, millimeter, radar and THz) and/or low absorption, a low defect count in bulk and surface, a uniform index variation, and no striae.

Applications - These characteristics are particularly ideal for laser windows, debris shields, beam splitters, filters, and mirrors.

Heraeus Optical Plates takes the heat - Fused silica’s unique thermal properties include a low coefficient of thermal expansion (CTE) (0.54/K(0-600C) and a high working temperature (strain point: 950 C, up to 1000 C). The result is optical plates with low expansion and high thermal shock resistance that can be used in extreme temperatures and rapid heating applications.

Applications - This is ideal for windows, ovens, furnaces, missiles, and high temperature thick and thin film coatings.

Heraeus Optical Plates takes punishment - The mechanical properties of fused silica include high hardness and material toughness, and a high tensile strength (N/mm2): 50, Bending: 67. These properties give Heraeus’ optical plates a high scratch resistance, high impact strength.

Applications - This is ideal for substrates and windows for scanners, or applications involving aerospace, aircraft, RPV, vacuums, or other harsh environments.

Heraeus Optical Plates resists harsh chemical environments & maintains high purity - Fused silica also offers high purity and a low etch rate to organic acids and alkali from a chemical properties perspective.

Applications - This is ideal for substrates/wafers to applications that require low contamination (like semiconductor wafer processing or bio-medical applications), or a high chemical durability.

Heraeus Optical Plates and Electro-Optical performance- Lastly, fused silica offers unique electrical properties such as high resistivity, high dielectric strength, and low dielectric loss.

Applications - This is ideal for optical plates used in high temperature insulators, radar, and microwave windows.

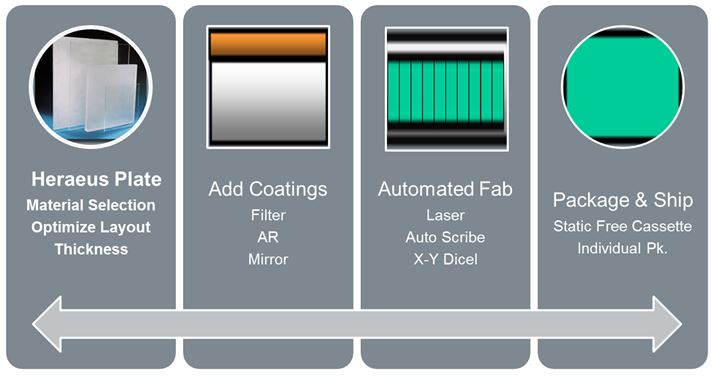

Heraeus Optical Plates Enable Cost Effective Production of plano optics – The cost for material-cutting-polishing has been optimized in large area format (up to 1m) removing most of the cost for plano optics – value can be added with optical coatings & automated cutting & packaging to produce final produce cost effective components with the desirable high performance properties described above.

Products with a competitive Edge - These unique characteristics give Heraeus’ optical plates a distinct advantage over other optical plate offerings. For more information on the unique benefits of Fused Quartz and Fused Silica, download the overview.

Contact Heraeus for more information.