Critical success factors to realizing maximum impact from your RTD implementation

The semiconductor industry has enthusiastically embraced the Theory of Constraints as explained by Eliyahu Goldratt in his book "The Goal." The Theory of Constraints (TOC) seeks to maximize system throughput and maintain a minimum level of inventory by effectively managing the constraint resource. Semiconductor fabs with their complex and reentrant processes, face several challenges in successfully implementing this theory. Managing a constraint or bottleneck resource in such processes is resultantly complex.

However with the introduction of AutoSimulations, Inc., a Brooks Automation Company Real Time Dispatcher (RTD), innovative new approaches are possible. This paper will describe the characteristics of a successful approach for managing the constraint resource, particularly the case of a recurring constraint resource, and will explain why the creation of a global dispatching policy provides a critical link in the value chain of an enterprise.

Beyond the creation of an effective dispatching algorithm, several other factors critical for a successful implementation will be discussed. These factors include cultural transition, organizational infrastructure, manufacturing performance metrics, education, communication, training, business processes, implementation strategy, and continuous improvement.

Contents

• Profitability and the value chain

• How to affect the value chain

• Implementing the theory of constraints

• Focus on the bottleneck

• Feeding the bottleneck

• The solution

• RTD: What it is and what it contributes

• Critical success factors

• Summary

Profitability and the value chain

The idea of global optimization is not unique to the manufacturing process, but should be applied to all of the processes associated with running a business. A business is, after all, a group of interrelated processes, and the goal of a business is to maximize the profit derived from those processes. A core discipline of managing a business for profitability has become known as Supply Chain Management. Supply Chain refers to the flow of materials and information required for the manufacture of products and services. The more inclusive term Value Chain refers to the flow of market information (such as demand) and cash into the system as well as the flow of products and services out of the system. Value Chain Management involves accelerating the velocity of business transacted along the chain, thus reducing the amount of money tied up in interim process steps and improving customer service. The links in this chain that contain the largest amount of inventory and consume the most operational expense (these terms will be defined in a moment) provide the largest opportunity for increased efficiency. For the semiconductor industry a major portion of the Value Chain resides within the walls of the wafer fab. This portion of the Value Chain consists of factory planning and factory floor dispatching. Factory planning is the process of analyzing the capacity of the fab based on the forecasted demand and product mix to ensure that the demand can be met. This analysis is used to establish a capacitated starts plan that will determine at what rate and in what order lots are introduced into the fab. Once material is in the manufacturing facility it is the responsibility of the dispatching system to move WIP in the most efficient manner. Of these two processes, the factory floor dispatching system generally has the greatest potential to improve economic profit.

Back to top

How to affect the value chain

We know that it is desirable to improve the factory level processes of the Value Chain, so now we must explore how to do this. The body of knowledge that characterizes the behavior of this portion of the value chain is called Factory Physics. Two of the most basic building blocks for Factory Physics are Little's Law and the Theory of Constraints. Little's Law establishes a relationship between queue length, arrival rates, and service times and was originally applied to a single queue or point of service. In factory level manufacturing terms the Law can be stated as:

- WIP = Cycle Time * Start Rate

The Theory of Constraints (TOC) is a broader concept that has application beyond just manufacturing. In it's most basic form, TOC says that the goal of business is to "Increase throughput while simultaneously reducing both inventory and operational expense". Goldratt further supplies the following definitions of terms. The throughput of a system "is the rate at which the system generates money through sales". In other words, value is not realized until the revenue is received. Inventory is defined as "all money the system has invested in purchasing things that it intends to sell". And "operational expense is the money the system spends turning inventory into throughput." The correlation to Little's Law is obvious, by reducing cycle time we can either increase the start rate or reduce inventory, and both options increase throughput. Additional benefits of reducing cycle time are the ability to satisfy customer demand more quickly and more rapid yield ramps by decreasing the feedback time for process development. The principles of Factory Physics clearly address our challenge of improving the efficiency of the Value Chain.

Back to top

Implementing the theory of constraints

So how do we implement the theory? Goldratt summarizes the principles for implementation of his philosophy as follows:

- The capacity of a system is dictated by the most constrained resource, called a bottleneck

- Capacity lost at the bottleneck can not be regained

- The bottleneck must never starve for work and should therefore be buffered against variability of feed

- To improve the capacity of the system requires elevating the bottleneck capacity

- Subordinate everything to the bottleneck

- Material should not be introduced into the system faster than it can be consumed by the bottleneck.

For semiconductor manufacturing we must expand this approach to address the additional issues of recurring bottlenecks. For example, what occurrence of the bottleneck do you run first? Does it matter? What is a practical approach for driving inventory to the bottleneck based on the bottleneck's consumption rate? As far back as 1988, Glassey and Lozinski discussed techniques to detect starvation of the bottleneck. Through the years Dr. Glassey has described various methods to accomplish this goal. The solutions have ranged from graphical assistance for operators to queue predictions based on simulation experiments. Dr. Glassey has also attacked the problem of regulating the flow of material into the process flow based on a linear control rule called descending control. These approaches have been influenced by the unavailability of real time data.

Back to top

Focus on the bottleneck

Since the throughput of the system is dictated by the bottleneck, let us take a moment to look at the factors that affect it.

- Process speed – governed by the design of the tool and the process.

- Down time – largely a factor of tool age and condition.

- Preventative maintenance time - based on a defined schedule.

- Idle due to operators – a management and resource issue.

- Idle due to no WIP – a dispatching issue.

- Setups – affected by product mix and dispatching policy.

Of these factors, setups and idle due to no WIP can be affected by dispatching policy. Therefore, the solution addressed by RTD should focus on reducing or eliminating these detractors. Avoiding idle time on the constraint tool involves all tool sets in the process while setup optimization is localized to the constraint tool itself.

Back to top

Feeding the bottleneck

Because the semiconductor process is reentrant, the constraint tools are encountered many times in the process at differing process rates. Our goal must be to feed the constraint tool and maintain a linear inventory profile. We do this by recognizing that we must not just feed the constraint tool, but that we must feed all occurrences of the constraint tool, and we must do it in a consistent and equitable manner. If we fail to recognize this, we could be faced with the circumstance where there are large amounts of inventory in front of the constraint tool, but it is all bound for a single occurrence of the tool with all other occurrences left dry. In this case we have created a bubble of inventory in one location and a hole in the inventory profile in other locations. A reentrant constraint must ensure that it feeds itself. We can also add to this the concept of maintaining a minimum buffer in front of each occurrence of the constraint to protect it from the inevitable disruptions and fluctuations that could impede a constant flow to the constraint.

Back to top

The solution

The solution presented here to the problem of how to feed the constraint is similar to a well known dispatching policy called critical ratio. Critical ratio is a method to drive dispatching decisions based strictly on customer due date, and is simply the time the lot is expected to take to complete divided by the time until it is needed to be complete. This ratio of expected/needed time gives a higher priority to product that is farther behind schedule. This same type of concept can be used to ensure that material arrives at the bottleneck tools on time.

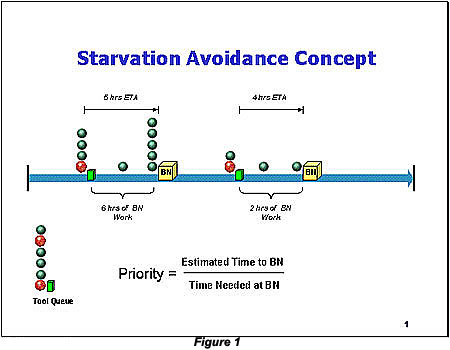

If we consider each occurrence of the constraint an end point, then we can drive work in process (WIP) to the constraint based on criteria relevant to the constraint tool. If our goal is to keep each occurrence of the tool from starving, then we can use the relationship between expected time of arrival and needed time. The expected time is the time for a lot to get to the constraint and the needed time is the time that the lot is needed at the constraint in order to keep it from starving (or depleting a minimum buffer). The more material that is in the constraint's buffer or is likely to arrive before the current lot, the lower the priority of the current lot will be (see figure 1 below). We now have a priority factor based on manufacturing efficiency needs that can be combined with more traditional drivers based on customer delivery dates. The combination provides a balanced and synergistic approach to scheduling.

RTD: What it is and what it contributes

We have discussed an interesting concept, but without a tool that can accomplish it, the discussion is academic. Fortunately, Real Time Dispatch represents a significant new capability in managing the manufacturing process. It provides a user- friendly interface that gives a nonprogrammer such as an Industrial Engineer or Manufacturing Engineer the ability to design, evaluate, and implement the exact functionality needed. The ability to access manufacturing data on a real time basis allows solutions not possible before. Rather than attempting to analyze recent conditions to predict future states in support of a manual decision process, rules can instantly assess the current dynamics of the manufacturing system and apply high function algorithms to them. This new level of capability is quickly nullified if used to simply automating existing rules of thumb. Rules of thumb are by definition only adequate solutions based on applying simple logic to limited information. Solutions that drive a competitive advantage should be based on Factory Physics concepts that drive global optimization and maximize the profitability of the business.

Back to top

Critical success factors

Practical experience has shown that simply designing and implementing a good dispatching rule, even one aimed at global optimization, does not yield successful results. Several additional factors have proven to be equally important in realizing the full benefits of a Real Time Dispatching solution.

Executive sponsorship and buy-in

The implementation of a new philosophy for operating the manufacturing facility will never get off the ground without the commitment and confidence of the management team. The executive management level must provide visible and consistent support for the effort.

Organizational structure

An RTD installation should be classified as a mission critical application. This is a software tool that requires dedicated resources for support of the hardware and repository as well as for the development and maintenance of the dispatching rules.

Formal manufacturing philosophy

It is crucial that a formal statement be published that describes the management team's approach to manufacturing. This will ensure that all rules implemented will conform to a common goal. RTD should be viewed as a tool to implement the management team's vision for efficient manufacturing.

Rule assessment/acceptance metrics

A consistent set of metrics should be established by which any new rules or rule modifications should be judged. This will ensure that rules are providing beneficial results to the fab. The metrics must be aligned with the manufacturing philosophy. Since the implementation of a rule will directly affect the productivity of the fab, rules should be tested via simulation to insure that the desired results are achieved. ASAP provides this capability.

Operations performance metrics

Actual manufacturing performance should also be measured against metrics that indicate adherence to the manufacturing philosophy. These metrics should measure contribution to bottom line manufacturing effectiveness. If these do not align, there will be no compliance to the dispatch policy!

Management reports supporting metrics

Managers have a strong tendency to manage according to the information that is available to them. Therefore it is very important to provide management reports that gauge the same metrics that the dispatching policy is designed to influence. Incentive and performance plans cannot be in conflict with the manufacturing philosophy.

Supply chain integration

Even a very advanced dispatching system cannot be effective if it is consistently over committed by an unachievable starts plan. The two systems must work in concert. The dispatching system must be integrated with the factory planning system in such a way that avoids conflict or overlap. For instance, the factory planning system should not attempt to schedule product movement within the manufacturing facility, but rather assess and predict inventory movement in order to provide an effective starts plan. Conversely, the dispatching system should not attempt to develop starts plans or predict plant capacity.

Robust procedures governing rule development

Since this is a mission critical application, a documented procedure should be in place to maintain good standards and to keep the process effective and under control. Procedures should define the rule submission, assessment, and development process. They should define standards for rule robustness, maintainability, and functionality. Rules must have defined criteria for approval to ensure global optimization, performance and screen design. A formal test plan for new rules will ensure quality code, and proper training and rollout plans will encourage user buy-in and support. Finally, there must be an open process for feedback on the rules to facilitate continuous improvement.

Back to top

Summary

This paper has discussed the role of Real Time Dispatcher (RTD) as a powerful inventory management tool as well as a critical link in the overall value chain of an enterprise. It also described the characteristics of a successful approach using RTD to avoid starvation of recurring bottleneck resources. Other critical success factors were highlighted that focused on the need for cultural transition, support structures, communication, education, and continuous improvement. These concepts have been proven in production environments and are already providing substantial economic returns for the companies who have implemented them.

Back to top

Author biography

Clay Rippenhagen is a Senior Manager of the semiconductor consulting practice at Avicon, where he is responsible for managing all aspects of defining and implementing semiconductor eValue Chain solutions as well as leading the development of Avicon's Austin, TX office. Prior to joining Avicon, he was the Industrial Engineering Supervisor at Advanced Micro Devices, responsible for the modeling, simulation and dispatching efforts in Fab 25. Mr. Rippenhagen previously spent 10 years with IBM as an Account Systems Engineer and Industrial Engineer. He graduated with a Bachelor of Science in Industrial Engineering from Texas A&M University, and has spoken at a number of semiconductor industry focused organizations including the Winter Simulation Conference in Washington, DC.

Back to top